Company

Your added value

We specialise in industrial heat technology and heat recovery and in this way we optimise value creation potential - strength that comes from the individuality of our products and high system competence on the part of our employees. We maintain a high level contact and consulting quality with the aim of a sustainable partnership with you as a customer. We provide tailored solutions through innovation, individuality and quality from more than 60 years of experience for worldwide applications. We distinguish ourselves from competitors with corporate structures above all through the individuality of our products and our willingness to act quickly and flexibly for you.

You have an individual need - We have just the solution for you, and thus always the best possible solution

You have an individual need - We have just the solution for you, and thus always the best possible solution

Our mission statement

Sustainable + individual - We build on sustainable partnerships on the basis of common successes and generate sustainable growth through individual solutions with a high degree of added value. We are a motivated team with highly qualified employees and we work together with our customers and suppliers in mutual esteem, recognition and respect. Overall, our international networking and employee-oriented workplace culture ensures our company's success.

Established network partnerships are the engine and key of our long-standing existence

Established network partnerships are the engine and key of our long-standing existence

60 years of experience

1952 first GEA company office in Berlin Lichterfelde | 1953 founding of GEA Wärmeaustauscher-Gesellschaft mbH, Berlin | 1955 new production in Berlin Neukölln, manufacture of coolers for air- and hydrogen-cooled electric machines | 1959 company renaming to GEA Wärmetauscher-Gesellschaft, Happel & Co., Berlin,

expansion of the product range with smooth tube heat exchangers, air heaters and air coolers | 1992 founding of GEA Wärme- und Anlagentechnik mbH, Berlin - Köpenick, product portfolio of GEA Wärmetauscher-Gesellschaft, Happel & Co., Berlin as well as industrial cooling systems systems and sales for various GEA companies | 2002 company renaming to GWA Gesellschaft für Wärme- und Anlagentechnik mbH | 2011 move to the new company headquarters Berlin - Grünau

Your worldwide reliable partner for all industrial heat technology and heat recovery applications

Your worldwide reliable partner for all industrial heat technology and heat recovery applications

Certificates

Our quality

We are certified according to the quality management system DIN EN ISO 9001 and KTA 1401. In order to meet the high quality requirements in the execution of business activities and in the realization of processes in the company, we deploy the following rules and regulations in their current version:- DIN, EN and ISO standards | AD 2000, ASME VIII and IX | KTA 1401 and other nuclear rules | Pressure Equipment and Machinery Guidelines | Information sheets and standards of the VDI / VDE | National safety standards | VDMA

Depending on the specifications in your request, additionally required regulations can be procured and applied

Depending on the specifications in your request, additionally required regulations can be procured and applied

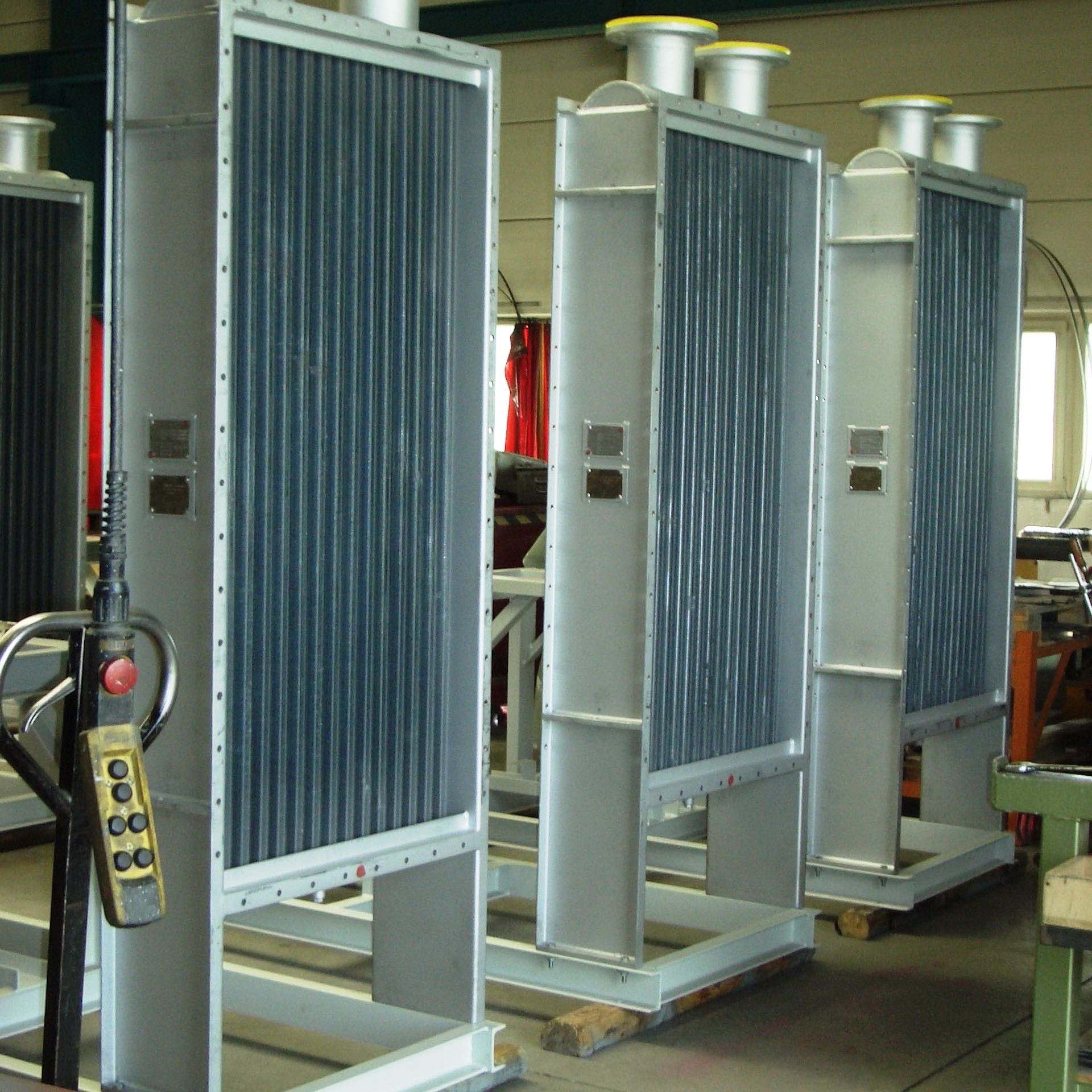

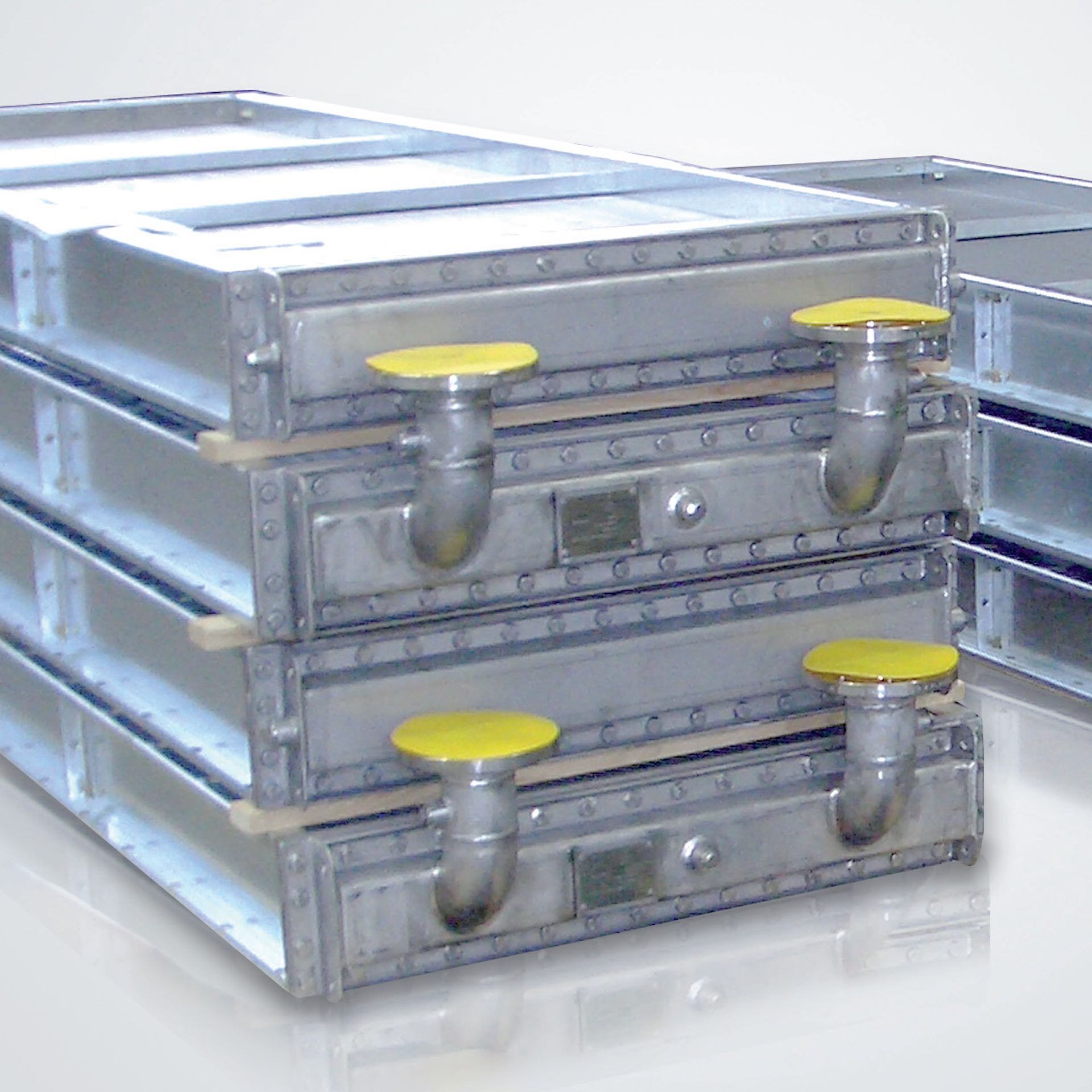

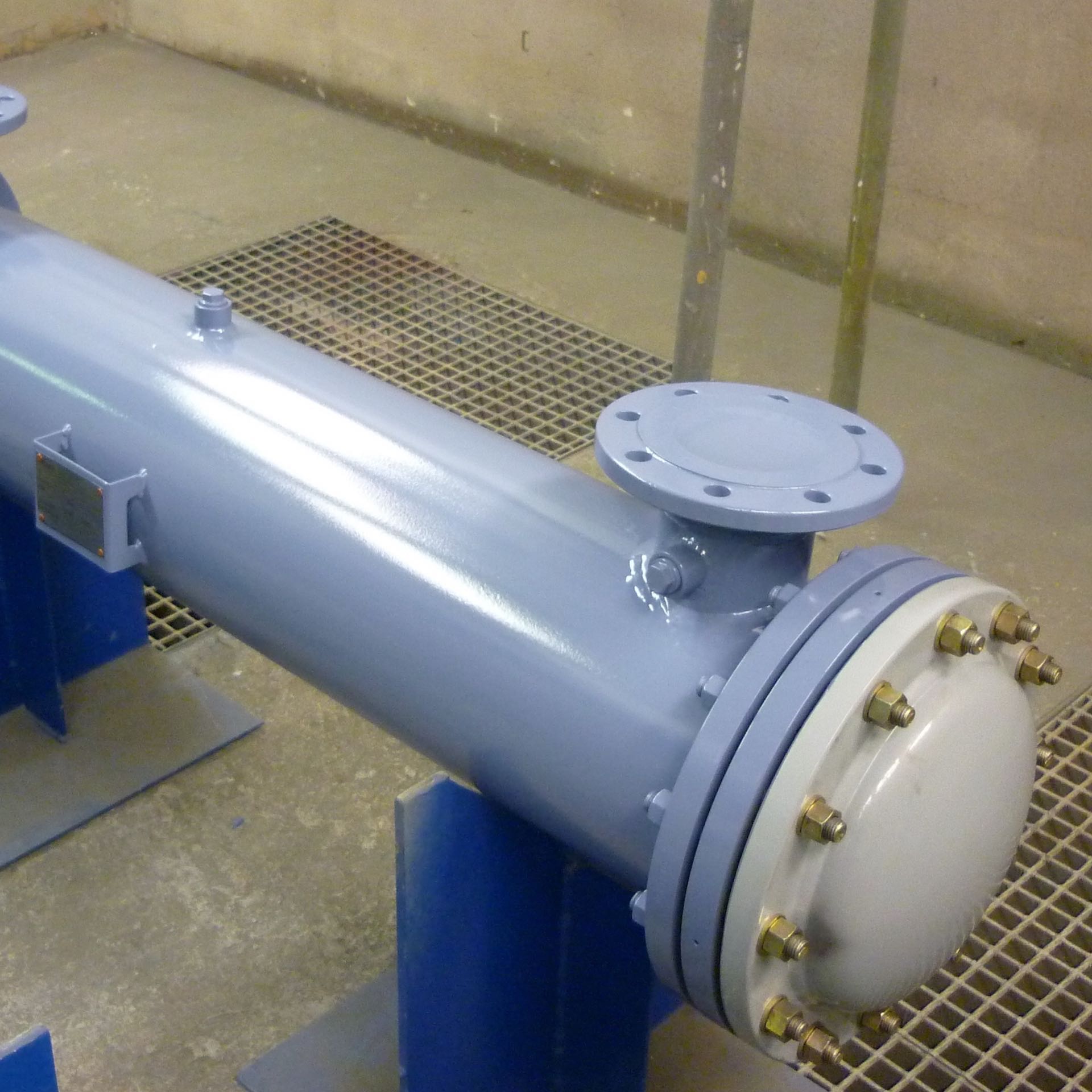

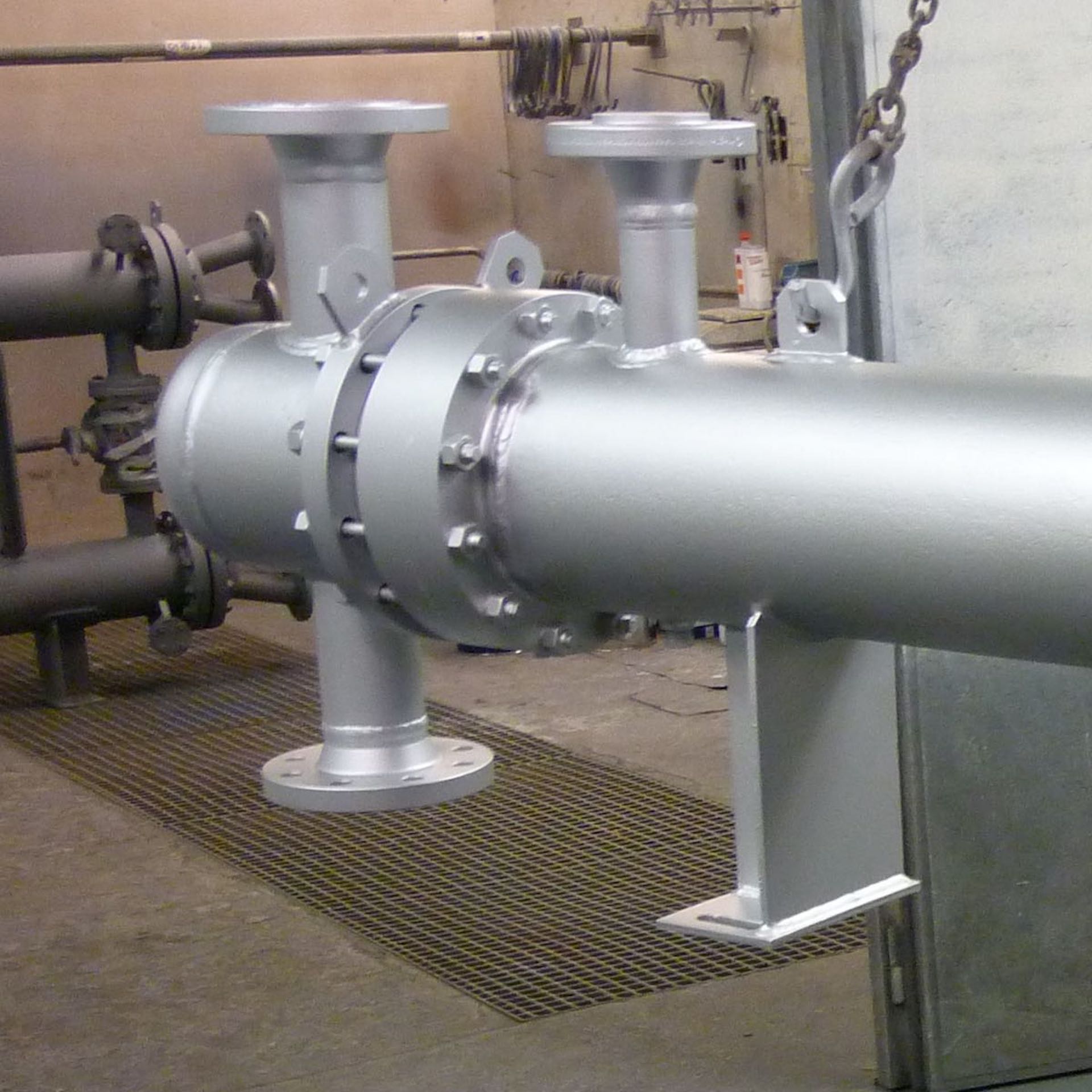

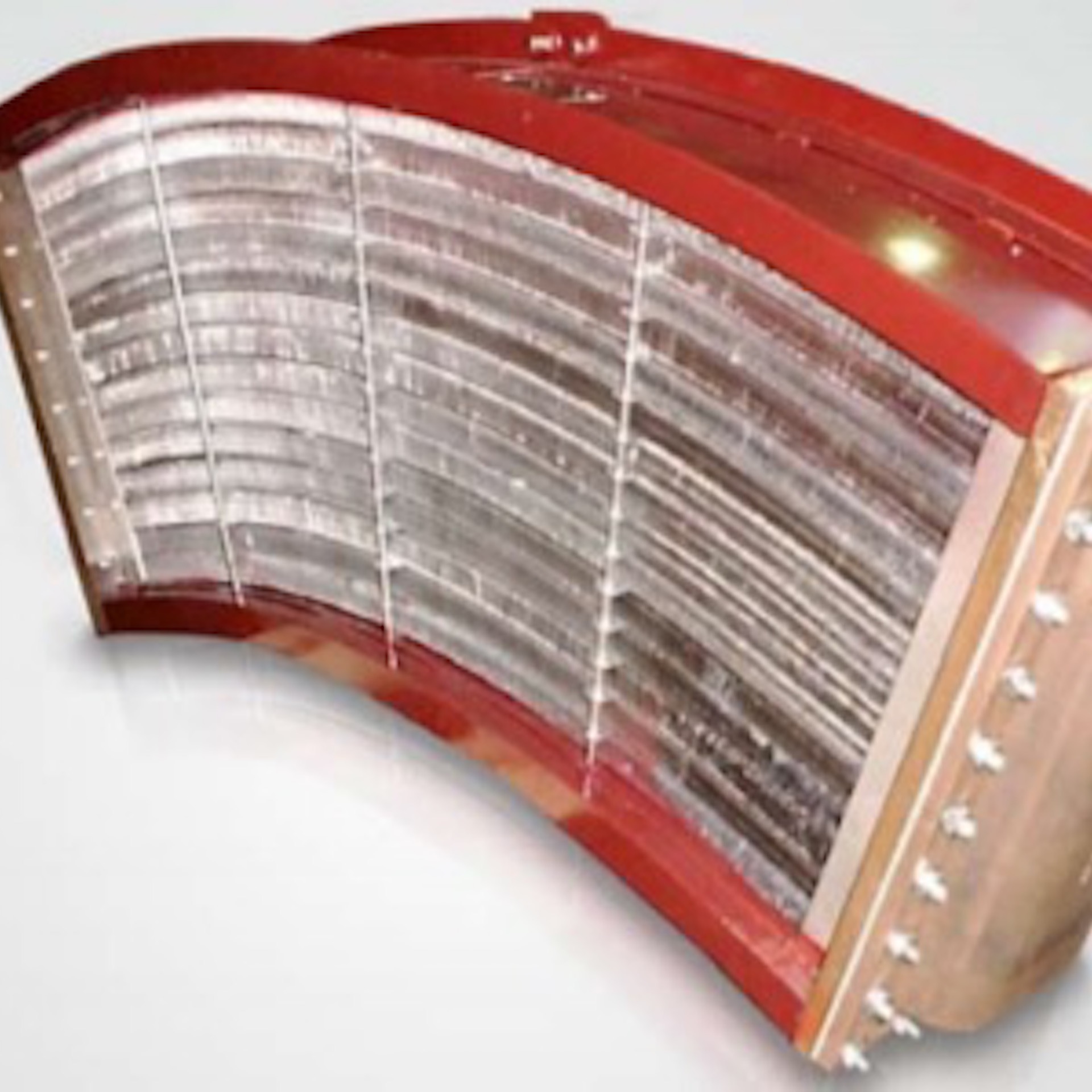

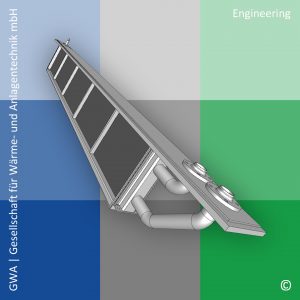

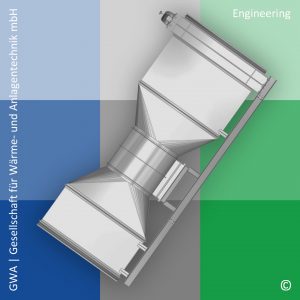

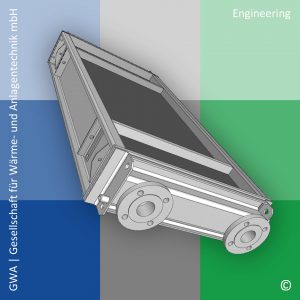

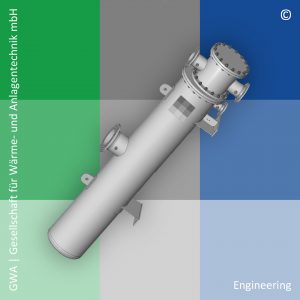

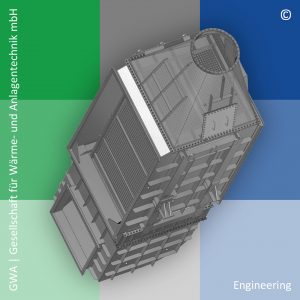

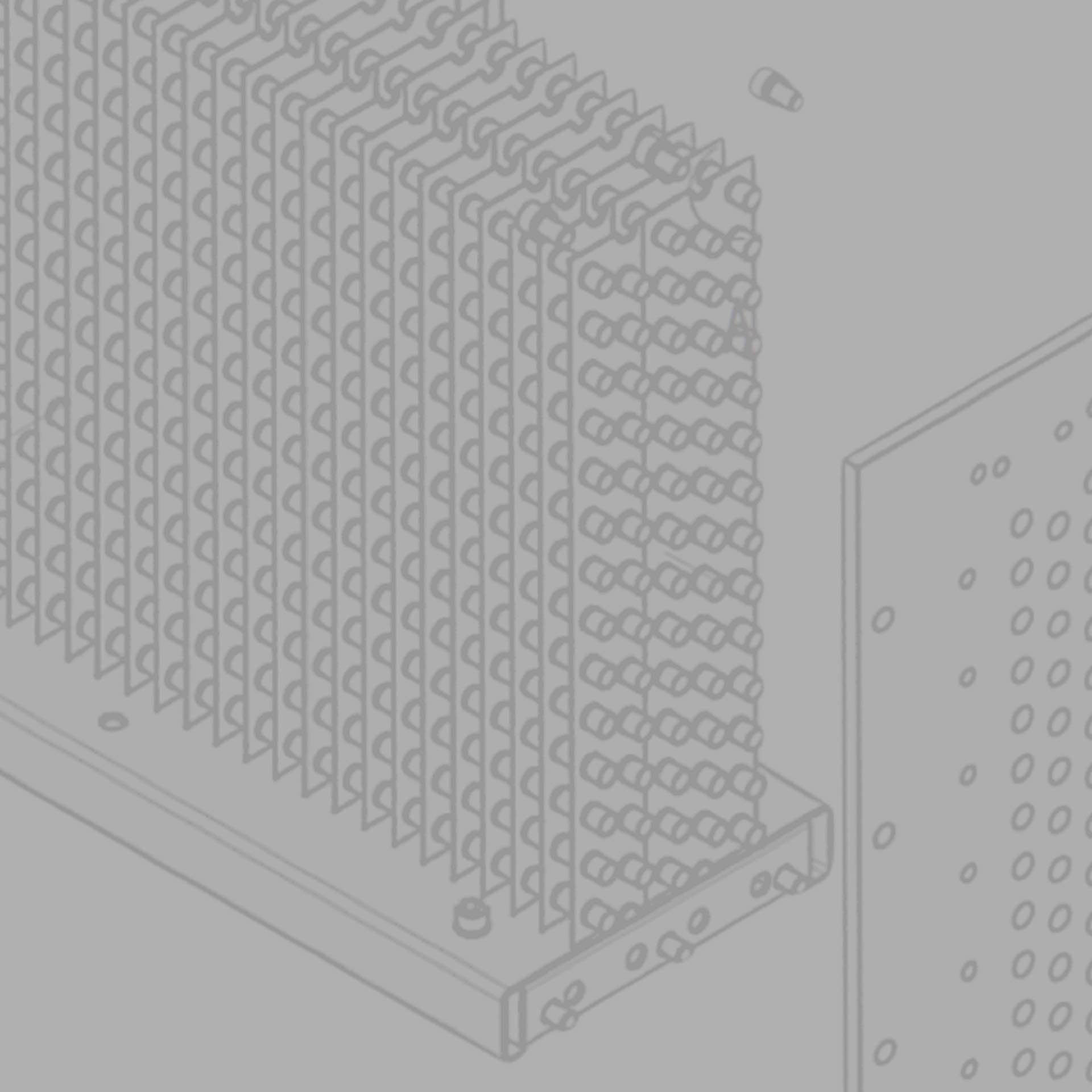

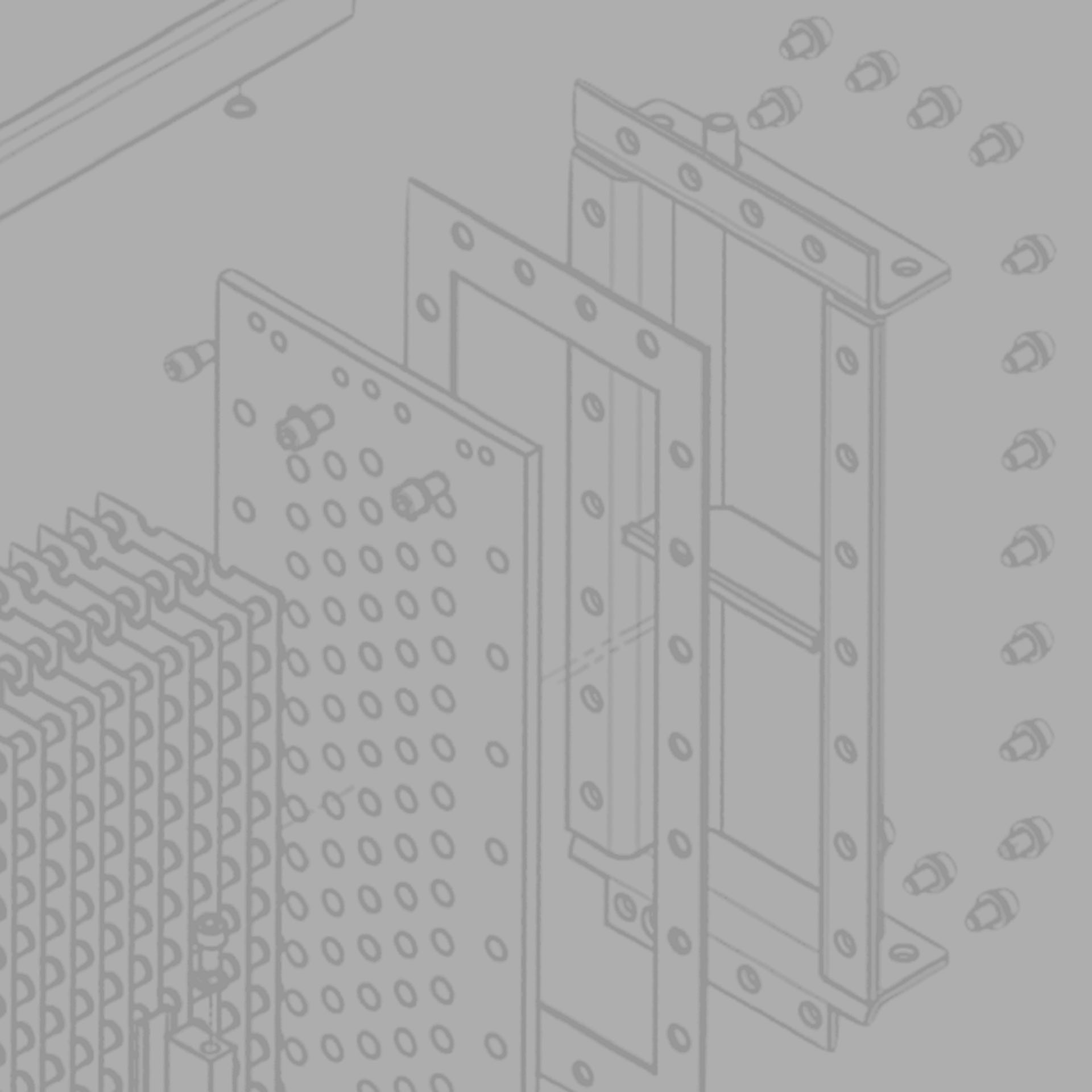

Heat exchangers

Heat exchangers can be found today in a wide variety of industries and applications. But they all have one thing in common: They help to save energy and thus costs. By using a heat exchanger, previously unused heat energy can be applied sensibly to other processes. This technology conserves resources and increases the efficiency of the entire installation.

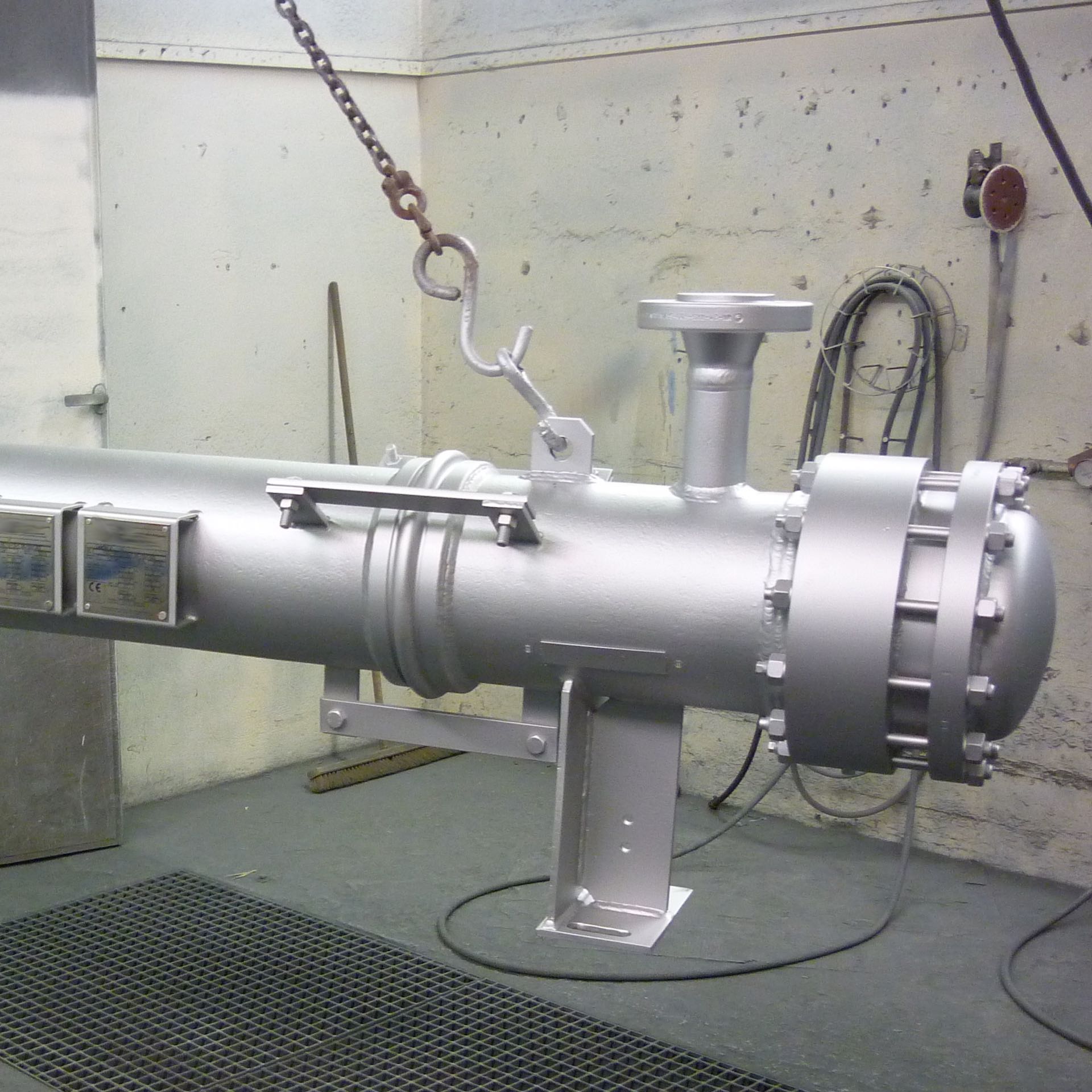

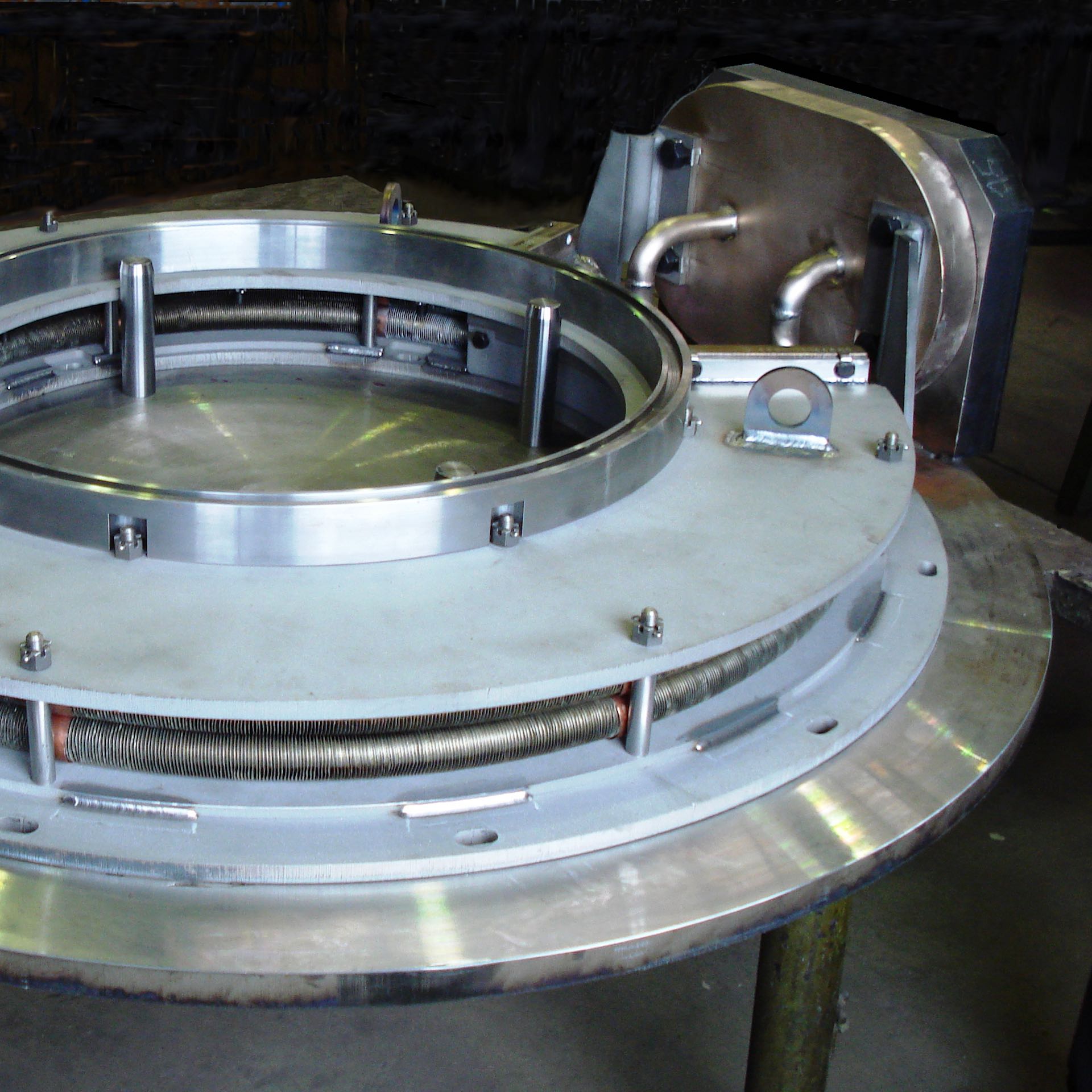

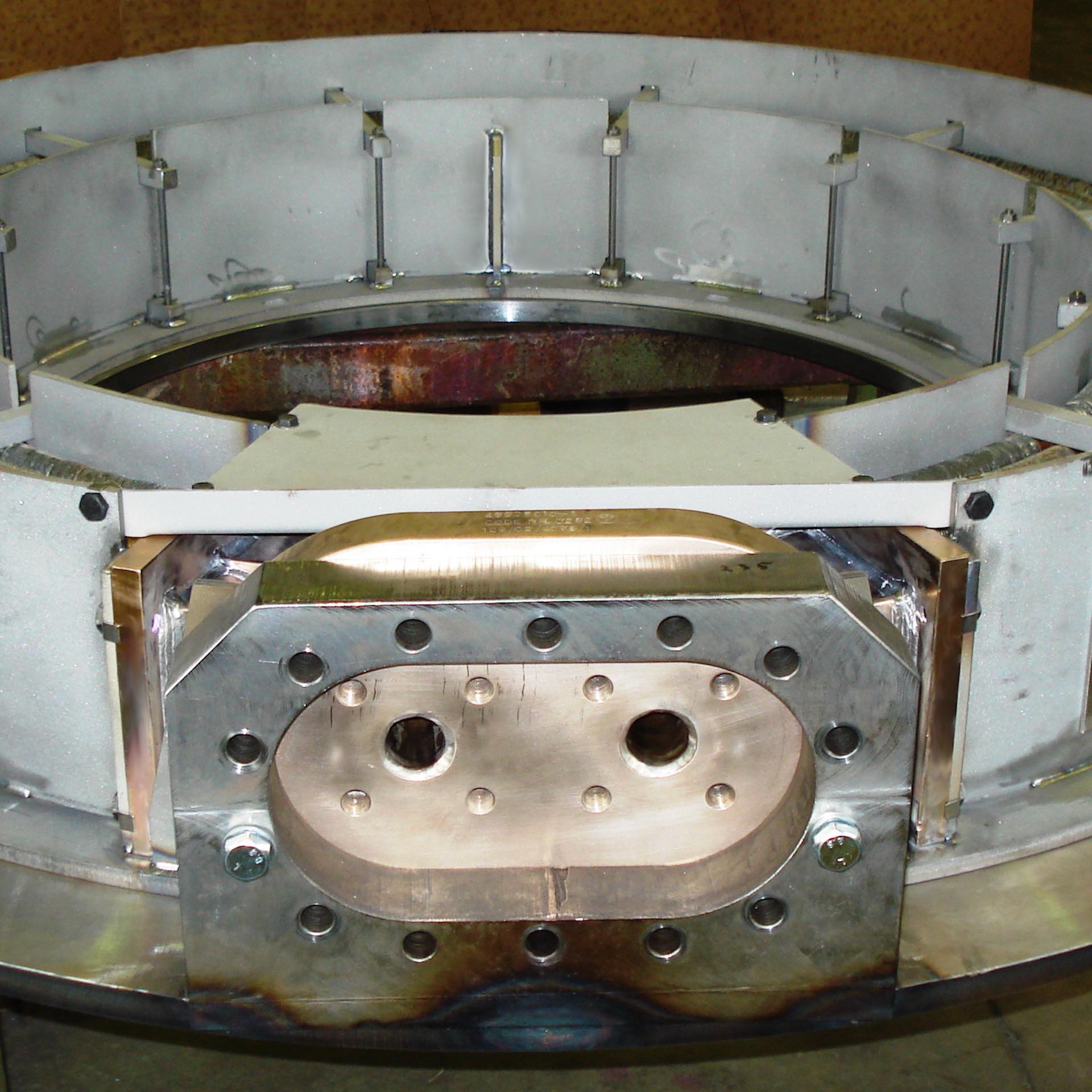

Individual designs are available for the individual requirements of our customers' technology industries: Rectangular design with smooth or finned tubes for connection to rectangular ducts, primarily heaters or coolers for gaseous media | Rectangular design with compact fin surface system especially for efficient cooling of electrical machines [e.g. for generators or motors] | Plate heat exchangers with corrugated profiled plates primarily for liquids | Cylindrical shell-and-tube heat exchangers with smooth or finned tubes for connection in the piping system for liquids, oils as well as with steam, air and gases | Ring type bearing oil coolers with smooth or finned tubes for connection in the bearing pot for cooling the turbine oils by means of cooling water

For an optimal solution, the heat exchanger is calculated individually for each application. Added value when using an individual heat exchanger: Waste heat utilization as value creation potential | Defined cooling of the output medium | Targeted cost reduction through energy saving | Increasing environmental and resource conservation | Higher profitability in the overall process

Individual designs are available for the individual requirements of our customers' technology industries: Rectangular design with smooth or finned tubes for connection to rectangular ducts, primarily heaters or coolers for gaseous media | Rectangular design with compact fin surface system especially for efficient cooling of electrical machines [e.g. for generators or motors] | Plate heat exchangers with corrugated profiled plates primarily for liquids | Cylindrical shell-and-tube heat exchangers with smooth or finned tubes for connection in the piping system for liquids, oils as well as with steam, air and gases | Ring type bearing oil coolers with smooth or finned tubes for connection in the bearing pot for cooling the turbine oils by means of cooling water

For an optimal solution, the heat exchanger is calculated individually for each application. Added value when using an individual heat exchanger: Waste heat utilization as value creation potential | Defined cooling of the output medium | Targeted cost reduction through energy saving | Increasing environmental and resource conservation | Higher profitability in the overall process

Spare parts + service

High-quality systems are a basic requirement for the safe functioning of your plant. That is why we place high demands on our products in terms of material selection and service life. The best way to ensure this for the long life cycle is to rely on original parts and service from the original manufacturer. GWA also offers the possibility of modernising individual components as well as complete apparatus and plant components to improve performance and reduce your total operating costs.

The exchange of other makes is also possible. Talk to us!

The exchange of other makes is also possible. Talk to us!

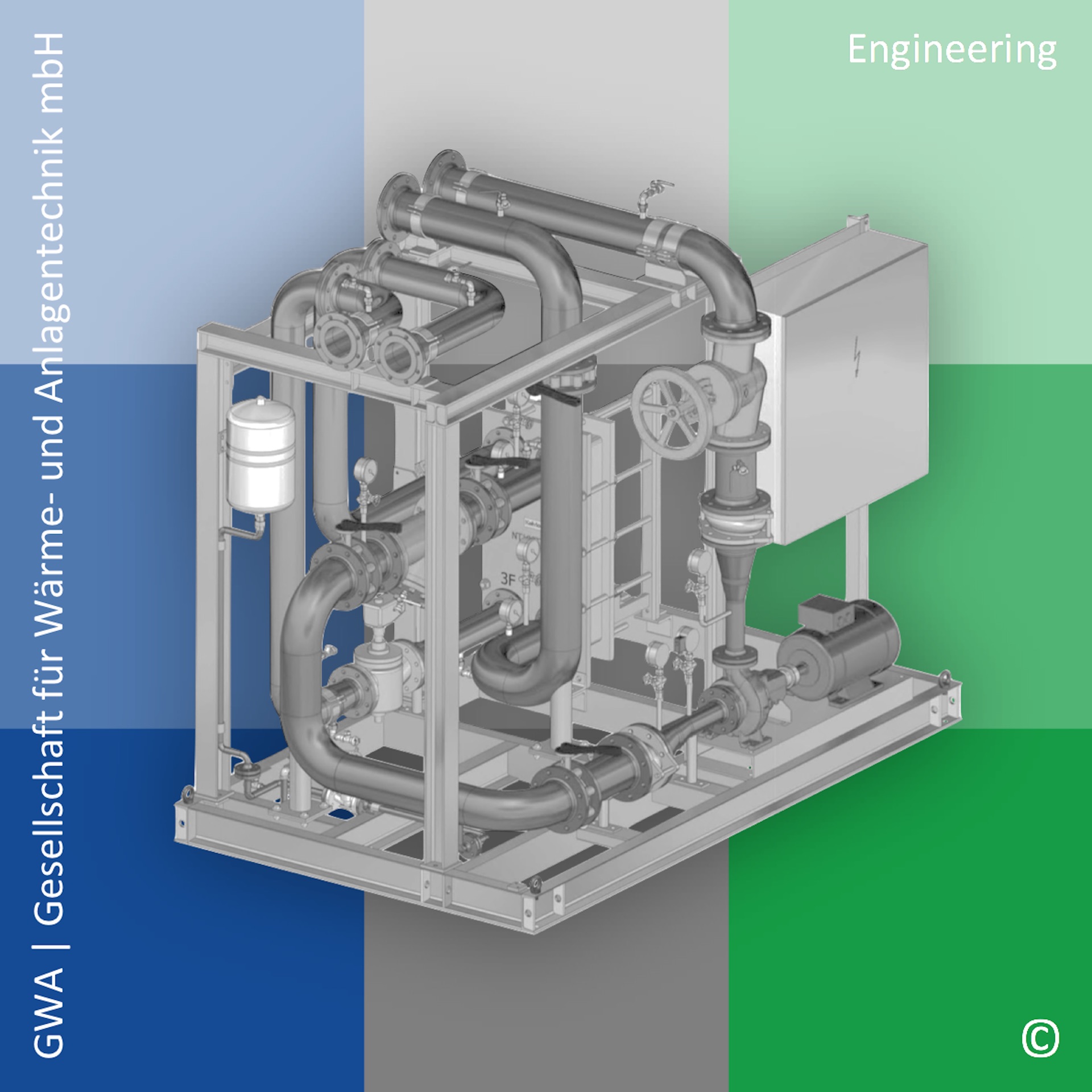

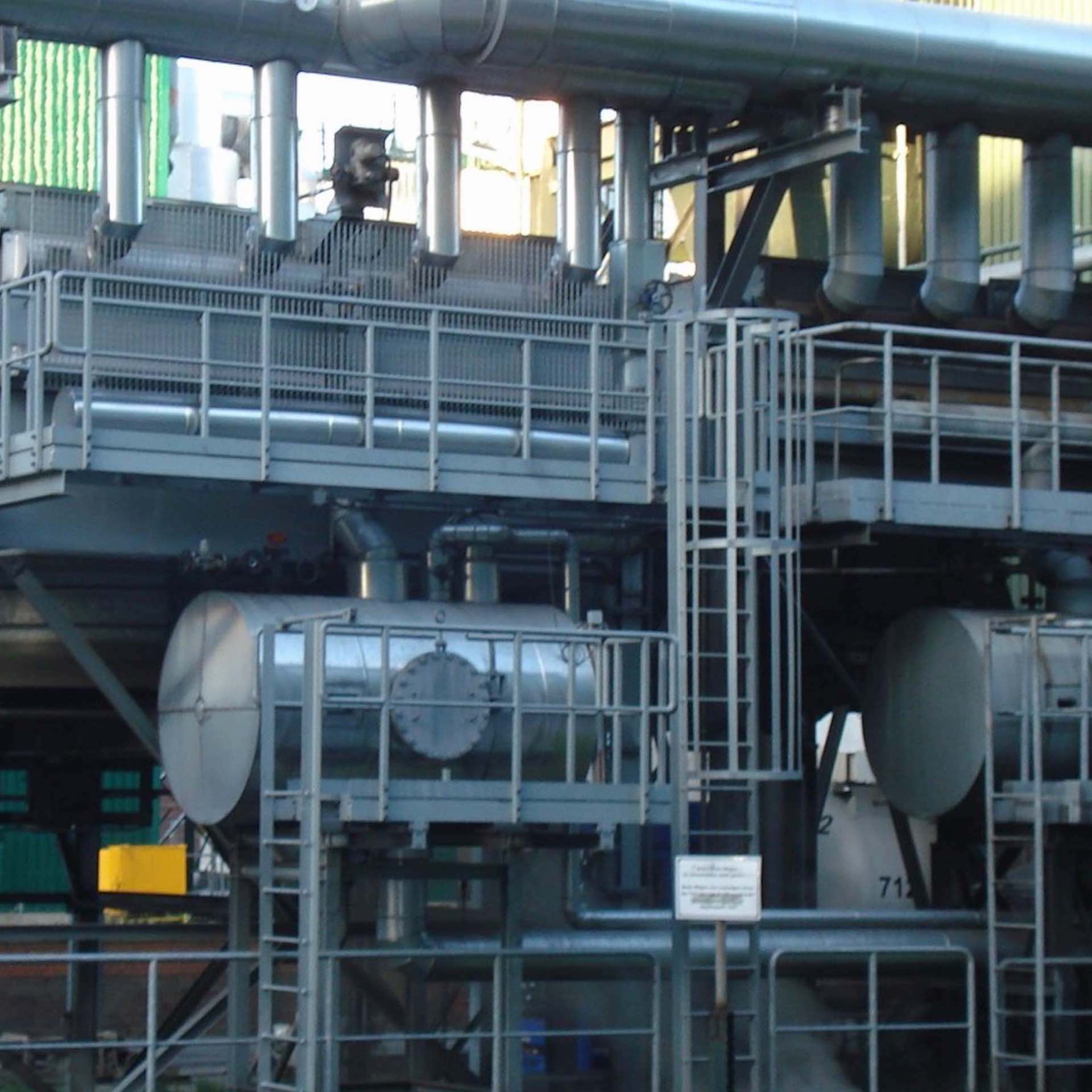

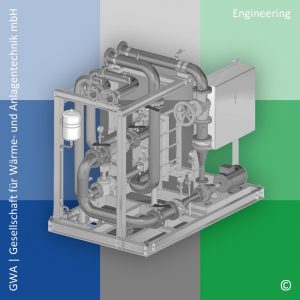

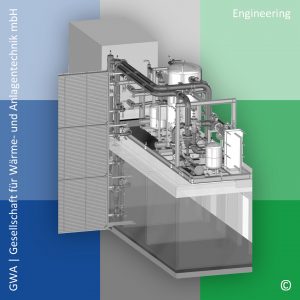

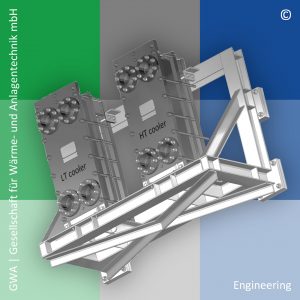

Cooling systems

We plan, design and manufacture complete cooling systems or sub-systems for industrial applications. All systems are designed and prefabricated for the special conditions of use in order to minimize the installation effort at the installation site.

Fields of application: Air preheating or "Anti-icing" of filter houses for gas turbine plants | Re-coolers[with or without pre-moistening] with high-performance tube system with fins or fins in air-cooled design including fan as part of complete cooling systems or as individual unit | Cooling towers in open or closed design as part of complete cooling systems or as individual unit (also possible as hybrid version) | Pump groups as skid systems ready for connection on base frame with expansion and header tanks including primary heat exchangers and their control valves

Fields of application: Air preheating or "Anti-icing" of filter houses for gas turbine plants | Re-coolers[with or without pre-moistening] with high-performance tube system with fins or fins in air-cooled design including fan as part of complete cooling systems or as individual unit | Cooling towers in open or closed design as part of complete cooling systems or as individual unit (also possible as hybrid version) | Pump groups as skid systems ready for connection on base frame with expansion and header tanks including primary heat exchangers and their control valves

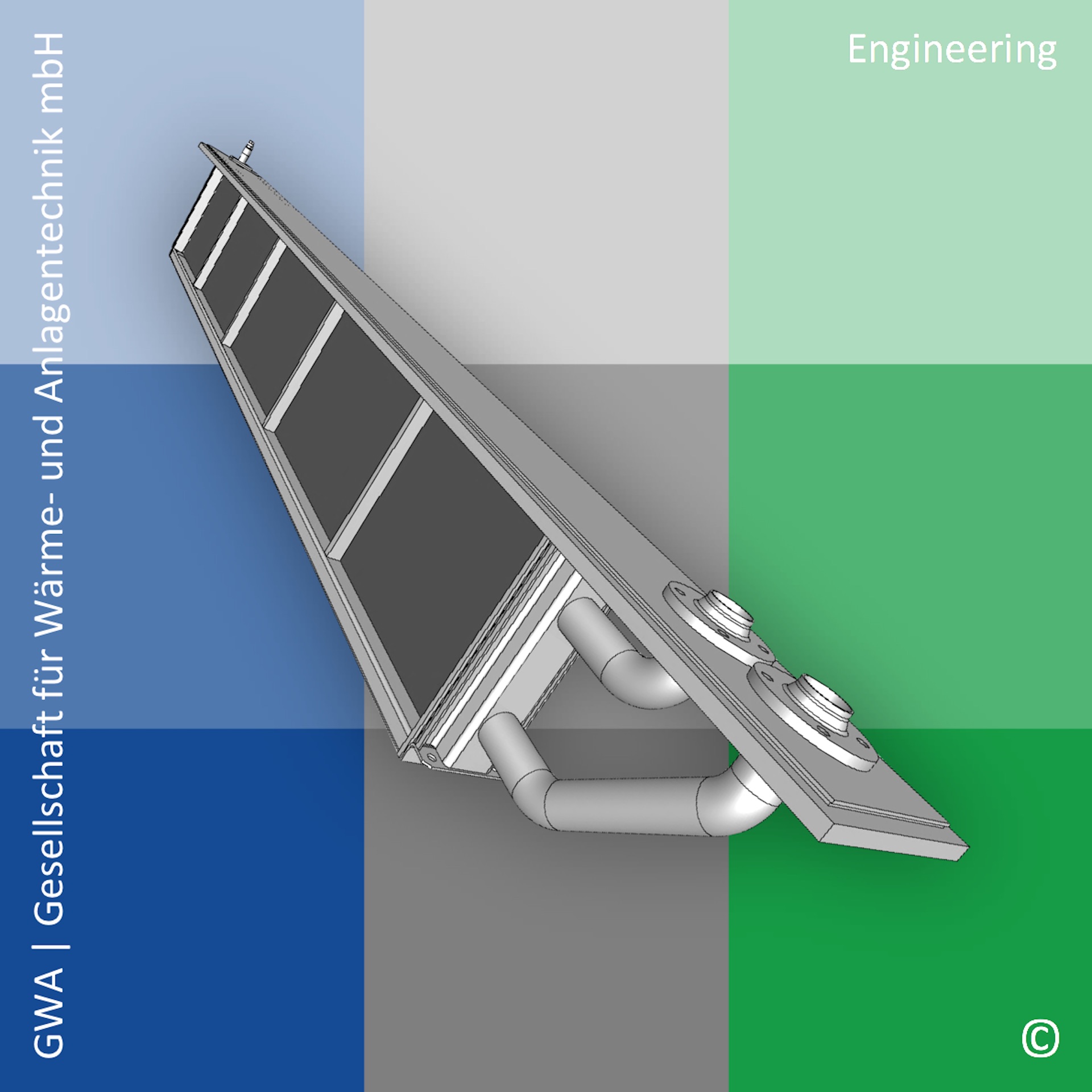

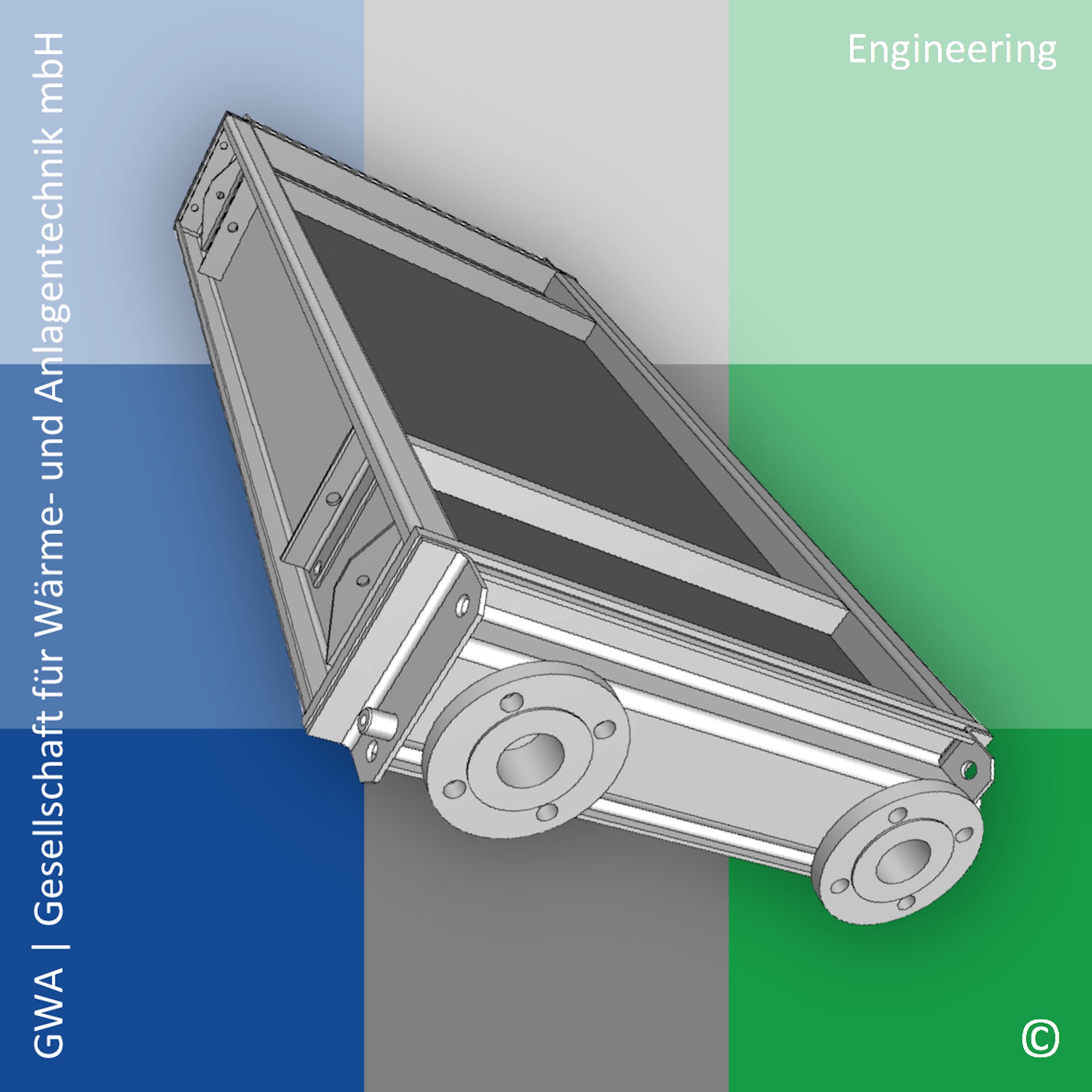

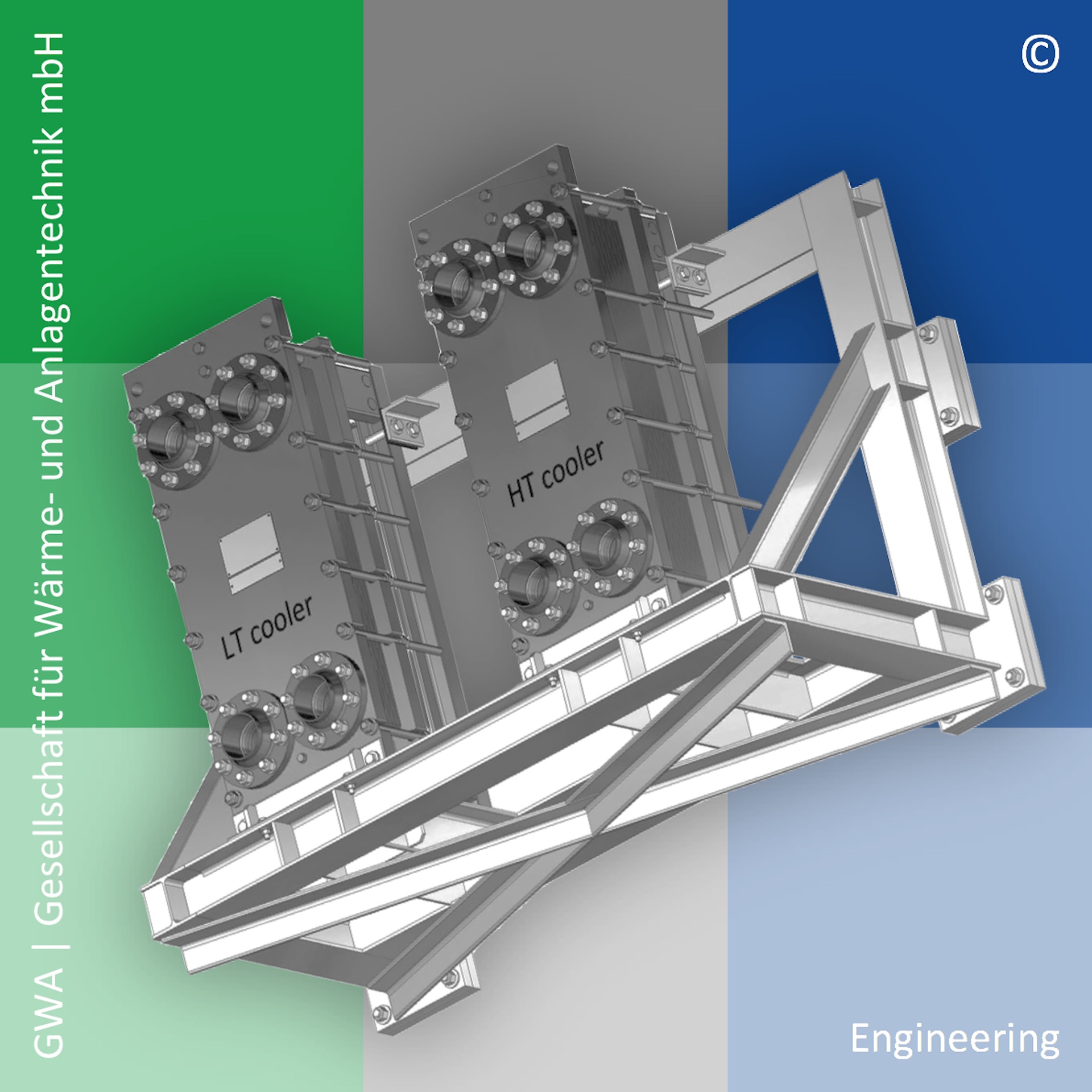

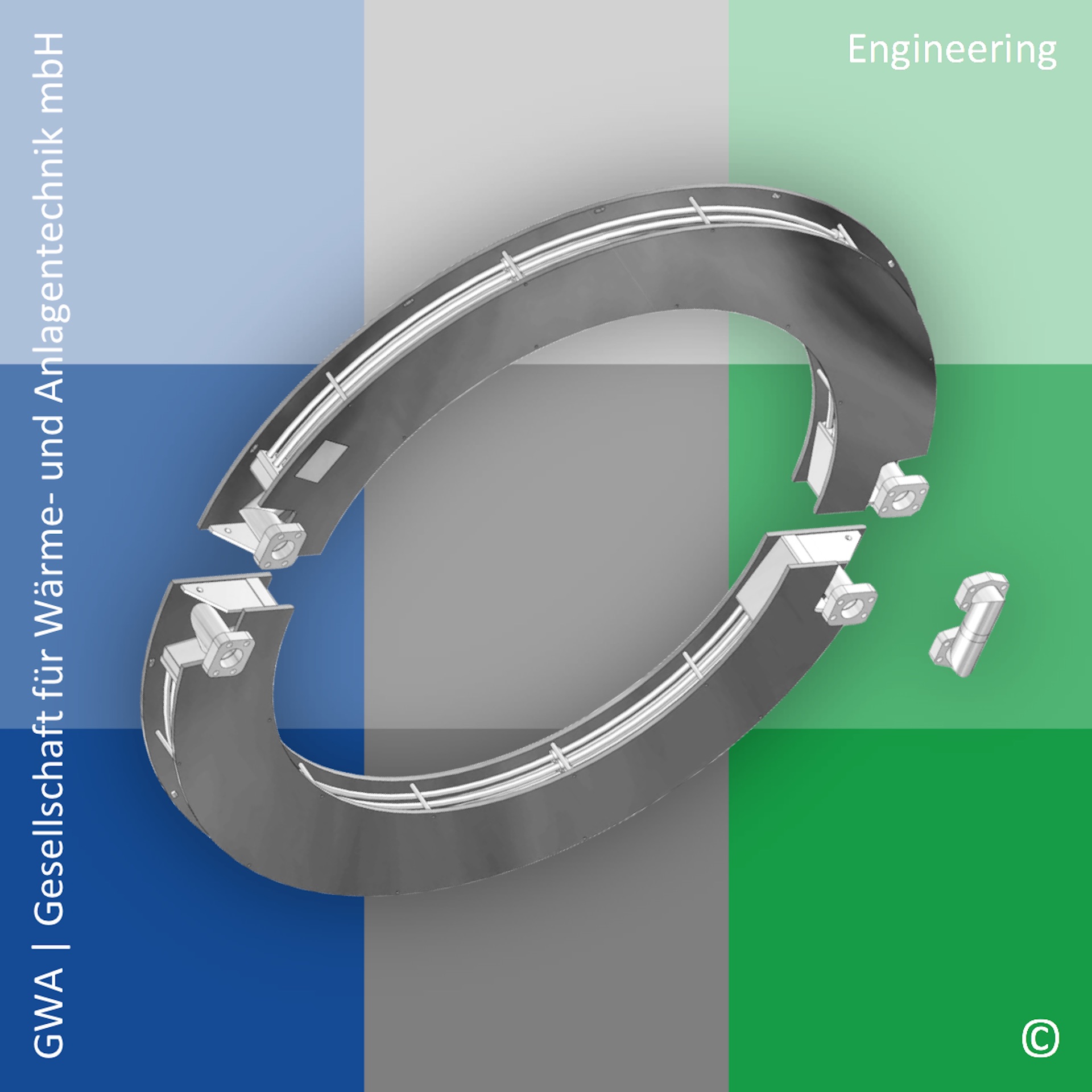

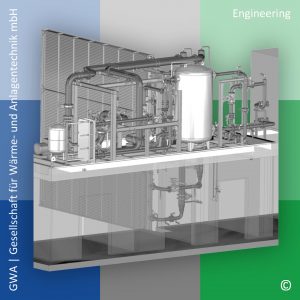

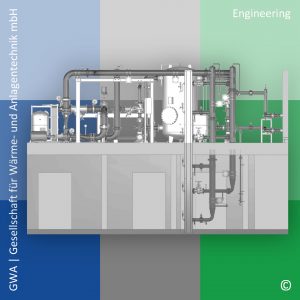

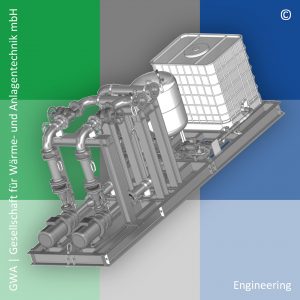

Engineering

We provide tailored solutions through innovation, individuality and quality from more than 60 years of experience in worldwide industrial heat technology and heat recovery applications. Our high system competence in the field of thermal and structural engineering enables planning and construction according to customer specifications, as well as national and international regulations and standards. As a special expertise, we are approved according to the KTA 1401 for the development, design, planning and delivery of heat exchangers, heater and cooling components. As a service provider, we will gladly take on the production of complete preliminary test documents for nuclear-technical apparatuses for you.

GWA manufactures its heat exchangers with competent subcontractors, who have the necessary manufacturing prerequisites and certifications according to the respective requirements, such as ISO 9001; AD 2000 Information Sheet - HP0; KTA 1401; ASME - U Stamp. In addition, we plan, design and deliver complete cooling systems or units for industrial applications. All systems are designed and prefabricated by our skilled engineering staff to the specific conditions of use in order to minimize the assembly work at the installation site.

GWA manufactures its heat exchangers with competent subcontractors, who have the necessary manufacturing prerequisites and certifications according to the respective requirements, such as ISO 9001; AD 2000 Information Sheet - HP0; KTA 1401; ASME - U Stamp. In addition, we plan, design and deliver complete cooling systems or units for industrial applications. All systems are designed and prefabricated by our skilled engineering staff to the specific conditions of use in order to minimize the assembly work at the installation site.

Career

Design innovation

A workplace that is not an ejection seat like in a group, but a consequence of continuous and positive business development. A solid and sustainable corporate culture. We support open exchange and fair interaction in the team, short decision-making processes and a high degree of personal responsibility.

Talk to us and become part of our team

Talk to us and become part of our team

Contact

Get answers

For questions about our products, or to request written information about them: Just contact us, we will be happy to help you. You can reach us on monday to friday from 8 am to 5 pm.

Please do not hesitate to get in touch using the contact form below

Please do not hesitate to get in touch using the contact form below